The medtech magazine DeviceMed recently featured Mebus MIM-Technik in an article showcasing the company’s expertise in producing highly complex, miniaturized components through Metal Injection Moulding (MIM) and Ceramic Injection Moulding (CIM). The publication underlined Mebus’ strategic role within the Acrotec Group and its capabilities in supporting demanding international medical projects.

In November 2024, the German company joined Acrotec, becoming the group’s center of excellence for MIM/CIM and technical plastic injection, with a strong focus on medical instruments, implants, and major European and US OEMs.

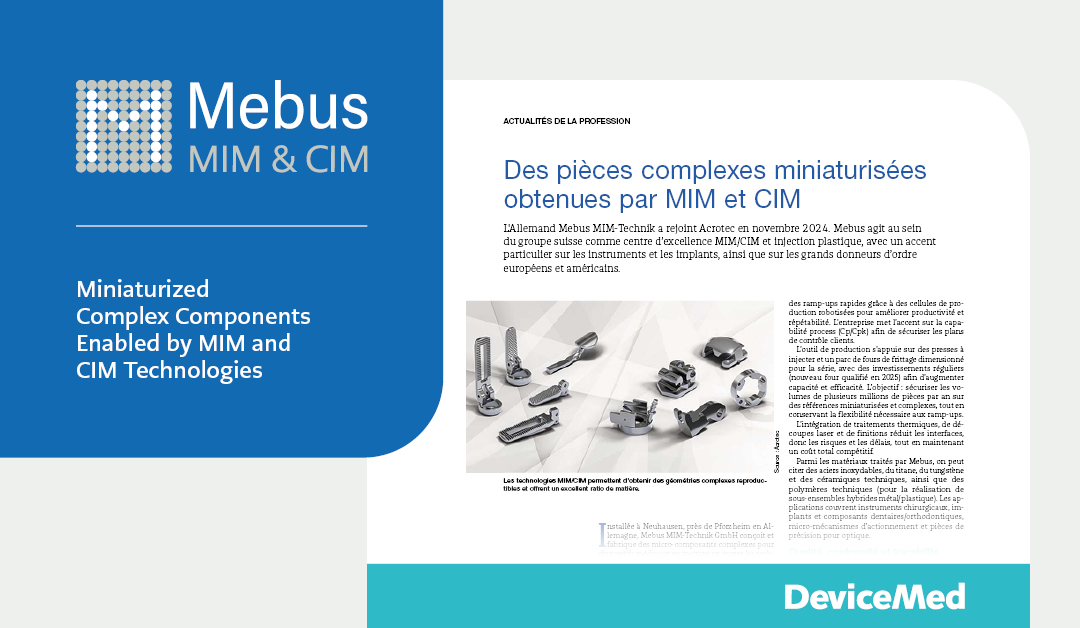

Located in Neuhausen near Stuttgart, Germany, Mebus designs and manufactures complex micro-components for medical devices, leveraging advanced MIM and CIM processes. DeviceMed emphasized the company’s strong reputation for delivering parts with challenging internal geometries, thin walls, and tight tolerances, from early prototypes to high-volume production.

Founded in 2005, the company now brings an elite team of exceptionally specialized professionals that fully support customers throughout the entire development workflow, from feasibility studies and design for MIM/CIM, to tooling, moulding, debinding, and sintering.

Robust Production Capabilities for Reliable Scale-Up

As highlighted by DeviceMed, Mebus showcases the essential advantages of MIM/CIM technologies for medtech:

- reproducible complex geometries

- competitive precision and scaling when machining or additive manufacturing becomes too costly

The company excels in solving manufacturing challenges often labeled as “impossible,” ensuring a robust transfer from prototype to serial production. Fast ramp-ups are achieved through robotic-assisted production, enhancing productivity and repeatability. Mebus places a strong emphasis on process capability metrics (Cp/Cpk) to secure customers’ quality and control requirements.

Its production equipment includes injection moulders and a sintering furnace park dimensioned for large-scale output. Regular investments, including a new furnace commissioned in 2025, strengthen capacity and efficiency. This allows Mebus to guarantee the delivery of several million miniature, complex parts per year, while maintaining the readiness required for scaling programs.

Integrated processes such as heat treatment, laser cutting, and finishing reduce interfaces, risks, and lead times, while keeping total cost competitive.

Materials processed at Mebus include various steels, titanium, tungsten, technical ceramics, and plastics. Applications cover surgical instruments, implants, dental/orthodontic components, micro-actuation mechanisms, and precision parts for optical systems.

Quality, Compliance and Full Traceability

The company is certified to ISO 13485 and ISO 9001, with a scope fully dedicated to MIM/CIM part production and technical plastic injection for the medical industry. Certifications demonstrate full process and batch traceability, offering customers a solid foundation for process qualification and audit documentation.

Strength and Added Value Within Acrotec Medtech

Since joining the Acrotec Group, Mebus operates as the organization’s center of excellence for MIM/CIM and plastics, supporting international medtech projects. This integration reinforces access to complementary capabilities, machining, surface treatments, assembly, while preserving the agility and technical depth of a specialized structure.